Mochini o ts'oarellang oa laser o tšoaroang ka letsoho

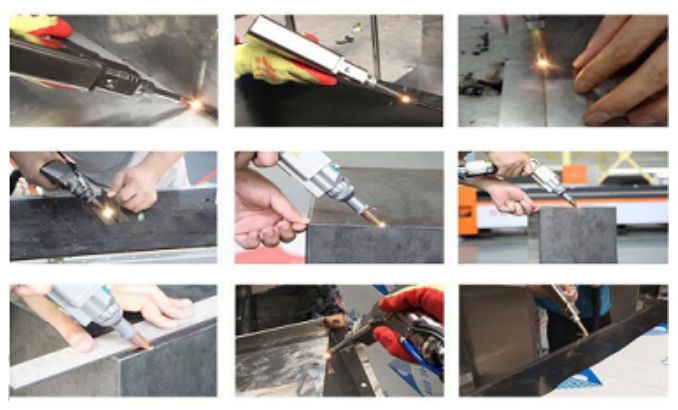

Laser welding ke ho sebelisa li-high-energy laser pulses ho futhumatsa sebaka sebakeng se senyenyane ka matla a phahameng a matla a laser pulses.Matla a mahlaseli a mahlaseli a laser a etsoa ka ho qhibilihisa thepa ka ho hasana ka hare ho lisebelisoa tsa tataiso ea mocheso ho etsa letamo le khethehileng la ho qhibiliha.Ke mofuta o mocha oa mokhoa oa ho cheselletsa.E etselitsoe haholo-holo ho cheselletsa lisebelisoa tse tšesaane tse nang le marako le likarolo tse nepahetseng.E ka hlokomela ntlha tjheseletsa, ho kopanya tjheseletsa, stacked tjheseletsa, ho tiisa tjheseletsa, joalo-joalo The karo-karolelano tebileng ke phahameng, bophara tjheseletsa ke nyenyane, mocheso ama sebaka ke tse nyenyane, 'me mocheso ama sebaka e nyenyane.Deformation e nyane, lebelo le potlakileng la welding, seams welding seams le aesthetics, ha ho kalafo kamora ho cheselletsa kapa ho sebetsa feela, boleng bo phahameng ba weld, ha ho na li-pores, taolo e nepahetseng, lintlha tse nyane tsa leseli, ho nepahala ha maemo a holimo, le ho fihlella habonolo ka boiketsetso.

Ha e le hantle, ho tla ba le thekiso e ntle haholo bakeng sa thepa ea mofuta ona oa welding, e amanang haholo le litšobotsi tsa eona, 'me litšobotsi tsena ka kakaretso li bonahala likarolong tse latelang.

1. Ts'ebetso ea welding e sebetsa hantle haholo.Lisebelisoa tse ngata tsa setso li ka tlisa litlamorao tse ntle ts'ebelisong ea 'nete ea ts'ebeliso, empa hobane ts'ebetso ea ts'ebetso e batla e lieha ha e sebelisoa, lits'ebetso tse fumanoang butle-butle lia fokotseha.Mochini oa welding oa laser ha o tšoane.U tlameha ho tseba hore ts'ebetso ea ts'ebetso ea welding e tlisoang ke mofuta ona oa lisebelisoa e phahame haholo.Ho bohlokoa ho boloka litlhoko tse itseng tse hloekileng nakong ea ts'ebetso eohle ea welding.

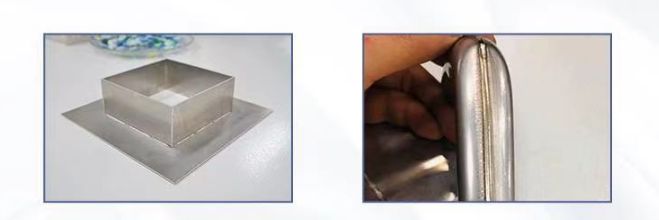

2. Phello ea welding e hlakile.Bakeng sa lisebelisoa tse ling tse thata tsa welding, hoa hlokahala ho sebelisa lisebelisoa tse tsoetseng pele tsa welding.Hobane lisebelisoa tse tsoetseng pele li ka fihlela litlamorao tse ntle tsa welding nakong ea ts'ebetso ea kopo, 'me ha li na phello leha e le efe ponahalong ea workpiece.Mechini ea tjheseletsa ea Laser ke lisebelisoa tse joalo, hangata ha ba kopana le li-workpieces tse nang le mathata a thata le ho feta, batho ba khetha ho sebelisa sesebelisoa sa mofuta ona.

| Mohlala | EC-1500/2000 |

| Matla a laser | 1500W/2000W |

| Laser wavelength | 1080nm 1064nm±5nm |

| Mokhoa oa laser | Mokhoa o le mong |

| Katleho ea phetoho ea photoelectric | 30% |

| Mofuta oa mosebetsi | tswelang pele |

| Bolelele ba fiber | 10m |

| Mofuta o phodileng | Pholiso ea metsi |

| Moetso o pholileng | 1500W / 2000W |

| Mocheso oa metsi a pholileng | 20-25 ℃ |

| Phepelo ea motlakase | AC220 AC380±10%,50/60Hz |

| Mocheso o sebetsang | 10 ~ 35 ℃ |

| Mongobo wa tikoloho ya mosebetsi | ≤95% |

| Sebaka sa ho fetola matla | 5-95% |

| Ho se tsitse ha matla | ≤2% |

| Phetiso ea fiber core bophara | 25um-50um |

Sanitary Ware tšimong ea bathroom sanitary ware, welding welding ea lipeipi tsa metsi, likhokahano tsa transformer, tse tharo, li-valve tsa heke le shaoara.

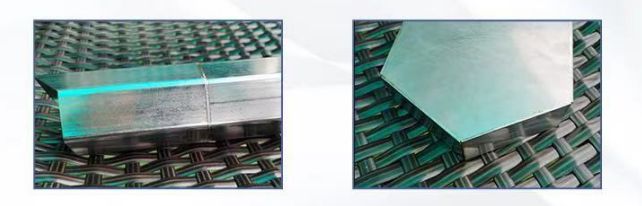

Indasteri ea tlhahiso ea likhalase: tjheseletsa e phahameng e nepahetseng ea lipoleiti tsa tšepe tse sa hloekang, motsoako oa aluminium le lisebelisoa tse ling tse kang sebopeho, moeli le likarolo tse ling tsa foreimi.

Indasteri ea Hardware: centrifugal impeller, teapot, lemati la mamati, joalo-joalo, welding ea likarolo tse thata tsa setempe, likarolo tsa tšepe tse entsoeng.

Ho etsa likoloi: li-cylinder pads tsa enjene ea koloi, li-hydraulic presses tse telele tse tjheseletsang, koloi ea spark plug welding, welding element welding, joalo-joalo.

Indasteri ea lisebelisoa tsa bongaka: lisebelisoa tsa bongaka, metjhini ea bongaka e tiisang likarolo tsa tšepe ea tšepe e sa tsitsang, le likarolo tsa welding ea likarolo.

Indasteri ea elektronike: ho tiisa tjheseletsa bohareng, ho tjheseletsa dihokelo tsa dihokelo, le tjheseletso ya dikgapetla tsa polasetiki tse kang mehala ya cellular le MP3 le dikarolo tsa yona.Motlakase tjheseletsa oa khetla enjene le mola o hokahantsoeng, optical faeba adaptara sehokedi.

Lelapa thepa, thepa kichineng, ntloana thepa bohloeki, tšepe e sa hloekang poleiti monyako hula matsoho, likarolo tsa elektronike, lisensara, lioache, mechine e nepahetseng, puisano, bonono le masimo a mang, mechine haeteroliki koloi le tse ling tse phahameng -khatello ho hanyetsa tšimong Welding tsena.

Mochini oohle o kenyelletsa likarolo tse latelang: mochini oa ho tjheseletsa, mochini o fepang terata, mitha ea khase ea argon, likhalase, lisebelisoa tsa hexagonal, liatlana, nozzle e tšehetsang, lense e sireletsang.

| Karolo ea lebitso | Bongata (sete) | Lebitso la lebitso |

| Sesebelisoa sa laser | 1 |

|

| Hlooho ea laser | 1 |

|

| Dual mocheso tse peli taolo chiller | 1 |

|

| Konopo ea ho fetola matla | 4 | Yijia |

| Motlakase oa motlakase | 1 | Yadeke |

| Khokahano ea AC | 2 | Zhengtai |

| Phetoho e kholo | 1 | Delixi |

Tiisetso e akaretsang ea mochini oa welding ke selemo se le seng ntle le khabinete.Lilense tsa laser, lilense tsa toche ea welding, le li-nozzles tsa koporo ke likarolo tse tlokotsing 'me ha li koaheloe ke waranti.