ECXT-3015 2000W/3000W faeba laser ho itšeha mochini

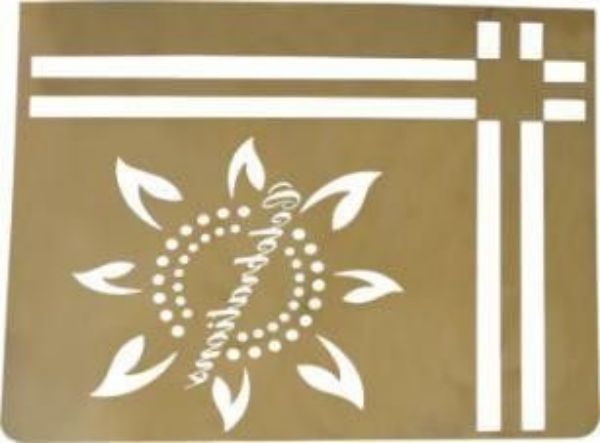

Ts'ebeliso ea mochini o potolohang oa servo motor le mochini o potolohang oa tataiso, ho nepahala ho holimo, ts'ebeliso ea software ea profeshenale, e ka lokoloha ho rala mefuta e fapaneng ea lits'oants'o tse lokelang ho etsoa kapa ho ngola mongolo hanghang, ts'ebetso e bonolo, ts'ebetso e bonolo, e bonolo.E sebelisoa ho itšeha ka lebelo le phahameng, ka lebelo le phahameng le botsitso.

1) Sebaka sa kopo

E loketse tšepe e sa hloekang, tšepe ea carbon, tšepe ea motsoako, tšepe ea silicon, poleiti ea tšepe ea galvanized, nickel titanium alloy, inconel alloy, titanium alloy le lisebelisoa tse ling tsa tšepe.

E sebelisoa haholo sebakeng sa sefofane, likoloi le likepe, tlhahiso ea mechini, tlhahiso ea lifti, tlhahiso ea papatso, tlhahiso ea lisebelisoa tsa ntlo, lisebelisoa tsa bongaka, hardware, mokhabiso, lits'ebeletso tsa ts'ebetso ea kantle ea tšepe le liindasteri tse ling tsa tlhahiso.

2) Melemo ea mochini oa ho itšeha oa laser fiber

1. Boleng bo botle ba boleng bo botle: sebaka se lebisang tlhokomelo se senyenyane, mohala oa ho itšeha o motle haholoanyane, katleho ea mosebetsi e phahame, 'me boleng ba ho sebetsa bo molemo;

2. Lebelo le phahameng haholo la ho itšeha: ke matla a tšoanang a CO2 laser cutting machine 2 linako;

3. Botsitso bo phahameng: tšebeliso ea laser fiber e phahameng ka ho fetisisa lefatšeng, ts'ebetso e tsitsitseng, likarolo tsa bohlokoa bophelo ba tšebeletso ho fihlela lihora tse 100,000;

4. Ho sebetsa ka mokhoa o phahameng ka ho fetisisa oa ho fetola motlakase oa motlakase: mochine oa ho itšeha oa fiber laser o phahame ka makhetlo a 2 ho feta CO2 laser cutting electro-optical conversion performance, ho boloka matla le ho sireletsa tikoloho;

5. Theko e tlaase haholo ea tšebeliso: tšebeliso ea matla ea mochine oohle ke 20- feela ea mechine e tšoanang ea CO2 laser cutting.

6. Litšenyehelo tse tlase haholo tsa tlhokomelo: ha ho na khase e sebetsang ea laser;Phetiso ea fiber ea optical, ha ho hlokahale lilense tse bonahatsang;Ho boloka litšenyehelo tse kholo tsa tlhokomelo ho ka finyelloa;

7. Ts'ebetso ea sehlahisoa le tlhokomelo e loketse: phetisetso ea fiber ea optical, ha ho hlokahale ho fetola tsela ea optical;

8. Super flexible light guide effect: boholo bo nyane, sebopeho sa compact, litlhoko tse bonolo tsa ho sebetsana le maemo.

3) Ho khaola mehlala ea ts'ebetso ea tlhahiso

| Mohlala | EC-3000W/2000W |

| Sebaka sa mosebetsi | 3000*1500W |

| Matla a phahameng a laser | 2000W/3000W |

| Phetoho e phahameng | Ho latedisa sefofane |

| Bophara bo fokolang ba mola | 0.15 limilimithara |

| Pulse frequency | 1-5000Hz |

| Pheta-pheta | ± 0.02 limilimithara |

| Sepheo sa ho beha maemo | Leseli le lefubelu |

| Phepelo ea motlakase | 380V/50Hz/60Hz/100A |

| Boholo ba mochini | 7880x3450x2000mm |

Lebitso la Nomoro ea Tloaelehileng Model/Series Quantity Manufacturer Name.

| Che. | Lebitso la sehlahisoa | Mohlala/letoto | Bongata | Moetsi |

| E 'ngoe | Laser jenereithara | |||

| 1 | Mohloli oa laser | 3000w/2000w | 1 sete | Patlisiso le nts'etsopele e kopaneng |

| Tse peli | Tsela ea kantle ea optical le hlooho ea ho itšeha | |||

| 1 | Hlooho ea ho itšeha ka laser | auto focus | 1 sete | Jiaqiang |

| Boraro | Moamoheli oa lisebelisoa tsa mochini | |||

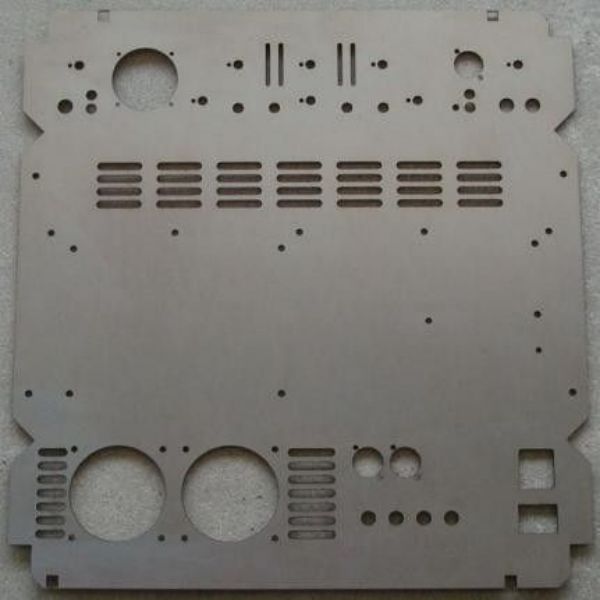

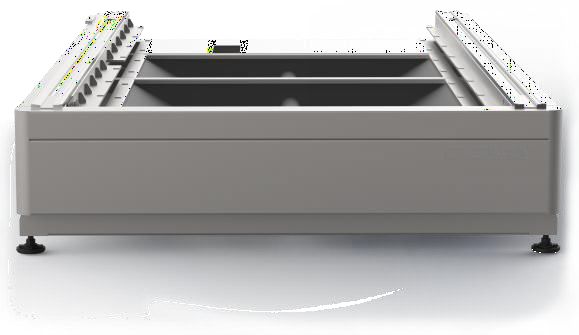

| 1 | Bethe ea mochini | 3015 sethaleng sa phapanyetsano | 1 sete | Setsebi se Khabane |

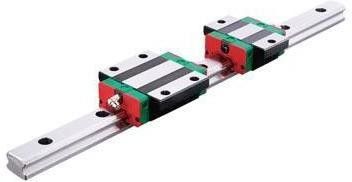

| 2 | Linear Guides | HGL HA2R | 2 lihlopha | Taiwan KING TEK |

| 3 | Servo motor le mokhanni |

| 4 lihlopha | Japane Fuji |

| 4 | XY axis planetary reducer | MAF-090 | 3 lihlopha | French Mordry |

| 5 | Helical gear / rack | YYC 2M | 2 lihlopha | YYC |

| 6 | Control cabinet |

| 1 sete | Setsebi se Khabane |

| 7 | Lisebelisoa tsa lisebelisoa tsa mochini |

| 1 sete | Setsebi se Khabane |

| Tse nne | CNC le sistimi ea software | |||

| 1 | Sistimi ea CNC | Bai chu | 1 sete | China Bai chu |

| 2 | K'homphieutha ea indasteri |

| 1 sete | Customized |

| 3 | Likarolo tsa motlakase |

| 1 sete | Schneider |

| Tse hlano | Lisebelisoa tse tloaelehileng | |||

| 1 | Precision Chiller | HL-3000/2000 | 1 sete | Wuhan Hanli |

| 2 | Mokhoa o ikemetseng oa ho tlatsa oli |

| 1 sete | motlakase |

| 3 | Indasteri kamehla mocheso moea conditioner |

| 1 sete |

|

| 4 | Sistimi ea ho felloa ke matla |

| 1 sete | pehelo ea liphaephe |

| 5 | Setsibotsi |

| 1 sete | customized |

| 6 | Ho amohela trolley |

| 1 sete | customized |

| Tšelela | Ts'ebetso e kholo ea ts'ebetso | |||

| 1 | Lebelo le phahameng | 1.2G | ||

| 2 | Ts'ebetso e kholo ea ts'ebetso | 120m/Mots | ||

| Mofuta oa thepa | Botenya (mm) | Lebelo (m/min) | Boemo ba ho tsepamisa maikutlo | Bolelele ba ho seha (mm) | Khase | Mofuta oa Nozzle | Khatello ea moea (bar) | Matla a laser (W) | maqhubu a ho itšeha (Hz ) | Mosebetsi cycle% | Phello ea ho khaola |

| Q235B Tšepe ea carbon | 1 | 38-40 | 0~-0.5 | 0.5 | N2 | lera le le leng1.0 | 12-16 | 3000 | 5000 | 100 | E benyang |

| 2 |

|

|

|

|

|

|

|

|

| ||

| 3 | 4~4.2 | 4.5~5.5 | 0.8 | O2 | lera habeli: 1.0 | 0.6~0,9 | 3000 | 5000 | 100 | ||

| 4 | 3.3~3.5 | 4.5~5.5 | 0.8 | O2 | lera habeli: 1.2 | 0.6~0,9 | 3000 | 5000 | 100 | ||

| 6 | 2.3~2.5 | 4.5~5.5 | 0.8 | O2 | lera habeli: 1.2 | 0.6~0,9 | 3000 | 5000 | 100 | ||

| 8 | 2.1~2.2 | 4.5~5.5 | 0.8 | O2 | lera habeli: 1.2 | 0.6~0,9 | 3000 | 5000 | 100 | ||

| 10 | 1.5 ~ 1.7 | 2~3 | 1.5 | O2 | lera habeli: 3.0 | 0.6~0,9 | 2200 ~ 2400 | 5000 | 100 | Poleshe e lerootho | |

| 12 | 1.2 ~ 1.4 | 2~3 | 1.5 | O2 | lera habeli: 3.0 | 0.6~0,9 | 2200 ~ 2400 | 5000 | 100 | ||

| 14 | 1~1.1 | 2~3 | 1.5 | O2 | lera habeli: 4.0 | 0.6~0,9 | 2200 ~ 2400 | 5000 | 100 | ||

| 16 | 0.85~0,9 | 2~3 | 1.5 | O2 | lera habeli: 4.0 | 0.6~0,9 | 2200 ~ 2400 | 5000 | 100 | ||

| 18 | 0.7~0,75 | 2~3 | 1.5 | O2 | lera habeli: 4.0 | 0.6~0,9 | 2200 ~ 2400 | 5000 | 100 | ||

| 20 | 0.6~0,65 | 2~3.5 | 1.5 | O2 | lera habeli: 4.0 | 0.6~0,9 | 2200 ~ 2400 | 5000 | 100 | ||

| 22 | 0.5~0,55 | 2~3.5 | 1.5 | O2 | lera habeli: 4.0 | 0.6~0,9 | 2200 ~ 2400 | 5000 | 100 | ||

| 25 | 0.45~0,5 | 2~3.5 | 1.5 | O2 | lera habeli: 5.0 | 0.6~0,9 | 2200 ~ 2500 | 5000 | 100 | ||

| SUS304 Ts'epe e sa beng le mabali | 1 | Lilemo tse 35-37 | 0~-1 | 0.5 | N2 | Lera le le leng: 1.0/1.2/1.5 | 12-16 | 3000 | 5000 | 100 | Slag mahala |

| 2 | 13-15 | -1.5~-2 | 0.5 | N2 | Lera le le leng: 1.5 / 2.0 | 12-16 | 3000 | 5000 | 100 | ||

| 3 | 7-8 | -2.5~-3 | 0.5 | N2 | Lera le le leng: 2.0/2.5/3.0 | 16-20 | 3000 | 5000 | 100 | ||

| 4 | 4.5~5.5 | -3.5~-4 | 0.5 | N2 | Lera le le leng: 3.0 | 16-20 | 3000 | 5000 | 100 | ||

| 6 | 1.7 ~ 1.9 | -5~-5.5 | 0.5 | N2 | Lera le le leng: 3.5 / 4.0 | 16-20 | 3000 | 5000 | 100 | ||

| 8 | 0.8~1.0 | -6~-7 | 0.5 | N2 | Lera le le leng: 4.0 | 16-20 | 3000 | 5000 | 100 | ||

| 10 | 0.6~0.7 | -7.5~-8.5 | 0.5 | N2 | Lera le le leng: 4.0 | 16-20 | 3000 | 5000 | 100 | Chelete e nyane ea slag e leketlileng | |

| AL aluminium Setšoantšo sa 6061 ) | 1 | Lilemo tse 30-33 | -0.5~-1 | 0.5 | N2 | Lera le le leng: 1.0/1.2/1.5 | 12-16 | 3000 | 5000 | 100 |

|

| 2 | 10-12 | -1~-1.5 | 0.5 | N2 | Lera le le leng: 1.5 / 2.0 | 12-16 | 3000 | 5000 | 100 |

| |

| 3 | 5.5~5.9 | -2.5~-3 | 0.5 | N2 | Lera le le leng: 2.0/2.5/3.0 | 16-20 | 3000 | 5000 | 100 |

| |

| 4 | 2.8~3.2 | -3.5~-4 | 0.5 | N2 | Lera le le leng: 3.0 | 16-20 | 3000 | 5000 | 100 |

| |

| 6 | 0.7~0.8 | -5~-5.5 | 0.5 | N2 | Lera le le leng: 3.5 / 4.0 | 16-20 | 3000 | 5000 | 100 |

| |

| 8 | 0.5~0.6 | -6~-7 | 0.5 | N2 | Lera le le leng: 4.0 | 16-20 | 3000 | 5000 | 100 |

| |

| Tšepe e mosehla | 1 |

|

|

|

|

|

|

|

|

|

|

| 2 |

|

|

|

|

|

|

|

|

|

| |

| 3 | 4.5~5 | -2~-2,5 | 0.5 | N2 | Lera le le leng: 2.0/2.5/3.0 | 16-20 | 3000 | 5000 | 100 |

| |

| 4 | 3~3.5 | -3~-3.5 | 0.5 | N2 | Lera le le leng: 3.0 | 16-20 | 3000 | 5000 | 100 |

| |

| 5 |

|

|

|

|

|

|

|

|

|

| |

| 6 | 1~1.2 | -5~-5.5 | 0.5 | N2 | Lera le le leng: 3.5 / 4.0 | 16-20 | 3000 | 5000 | 100 |

| |

| 8 |

|

|

|

|

|

|

|

|

|

| |

| Litlhaloso | 1, Litabeng tsa ho itšeha, bophara ba mantlha ba fiber ea laser ea 3000W ke li-microns tse 100; | ||||||||||

| 2, data ena ea ho itšeha e sebelisa hlooho ea ho itšeha ea Jiaqiang, karo-karolelano ea optical ke 100/125 (collimation/focusing mirror focus length) | |||||||||||

| 3, Ho khaola khase e thusang: oksijene ea metsi (bohloeki 99.6%) metsi a naetrojene (bohloeki 99.995%); | |||||||||||

| 4, Ka lebaka la ho se tšoane ha thepa ea thepa le mokhoa oa ho itšeha (sesebelisoa sa mochine, pholileng ea metsi, tikoloho, ho khaola khase ea khase le khatello ea khase, joalo-joalo) e amoheloang ke bareki ba fapaneng, lintlha tsena ke tsa ho bua feela. | |||||||||||

(1) BedThe Bed e amohela sebopeho se nang le tokelo ea molao sa Chaoxing Group, 'me phekolo ea phekolo ea khatello ea botsofali ka kakaretso e phethoa ka nako e le' ngoe e nepahetseng ea mochine oa mochine o moholo oa mochine ho etsa bonnete ba hore ho na le botsitso bo phahameng, ho nepahala le botsitso;

(2) Liraka tsa likere le litšepe tse tataisang

Rack le pinion: Taiwan precision helical rack le pinion, P-class linear guide e le likarolo tsa phetisetso, ho nepahala ho phahameng le lebelo le phahameng.

Lithaelese tsa tataiso: Ho sebelisoa litataiso tsa mela ea Taiwan, 'me litataiso tse nepahetseng tsa mehala e boima tse nang le moralo o ntlafalitsoeng oa sebopeho lia kopanngoa.Ha ho bapisoa le litataiso tse ling tsa mela, mojaro le ho tiea lia ntlafatsoa;e na le melemo ea lebelo le phahameng, mojaro o phahameng, ho tiea ho phahameng le ho nepahala ho phahameng.

(2) Servo motor

E sebelisa li-motor tsa servo tsa Majapane, e na le lebelo le potlakileng la karabelo, 'me e hlokomela monyetla oa ho beha maemo a holimo.Botsitso bo phahameng, ho nepahala ho phahameng le ho hloka tlhokomelo.

(4) Mofokoli

Amohela se fokotsang thepa e tsoang kantle ho naha.

molemo:

Ho nepahala ho phahameng: ho khutlela morao ka tlase ho metsotso ea 3 arc, boemo bo nepahetseng.

Boima bo phahameng, torque e phahameng: Tšebeliso ea li-roller bearings e ntlafatsa haholo ho tiea le torque.

No Grease Leakage: Sebelisa grease e nang le viscosity e phahameng, e thata ho arola ho thibela ka katleho ho lutla ha mafura.

Tlhokomelo e bonolo: ha ho hlokahale ho fetola mafura nakong ea bophelo ba sehlahisoa.

(5) Fiber laser jenereithara

Khetha lipatlisiso tse kopaneng le nts'etsopele ea jenereithara ea laser ea fiber, melemo ea jenereithara ea laser:

▲ Sekhahla se phahameng sa phetoho ea electro-optical

▲ Boleng bo botle ba borali

▲ Bophelo bo bolelele ba tšebeletso

▲ Theko e tlase ea tšebeliso e felletseng

▲ Tlhokomelo mahala

6. Likarolo tsa hlooho ea fiber laser:

1. Adopt QBH interface, e ka ikamahanyang le lihlahisoa tsohle tsa fiber lasers ka sehokelo sa QBH.

2. Moralo o se nang lerole oa seipone se sireletsang se kopanyang se entsoeng ke patente ea ho qaptjoa.

3. Phetoho e ikemetseng ea ho tsepamisa maikutlo, lebelo le potlakileng, ho nepahala ho phahameng le ts'ebetso e bonolo.

(7) Sistimi ea taolo:

Sistimi ea taolo ea CNC e na le likarolo tsa mantlha tse kang sistimi ea taolo ea PC, mokhanni le enjene ea eona ea servo.Sistimi e khethehileng ea laser CNC e amohetsoe, e emelang sistimi e sebetsang ka ho fetesisa ea laser CNC.CNC e kopanetsoeng le e tloaelehileng e kopana le litlhoko tsa basebelisi ba sebelisang mekhoa e phahameng ea ts'ebetso ea CNC ka tekanyo e ntle ea theko / tshebetso.

Tshebetso e phahameng

Theknoloji ea boemo ba pele le katleho

Theknoloji e ncha ea CNC le meralo e bulehileng ea CNC e nang le Intel dual-core CPUs li fa basebelisi monyetla oa ho khetha likarolo tsa CNC le ts'ebetso e le 'ngoe ea pele ea CNC.

Sebopeho sa modular

lHo sebetsa ka lebelo le phahameng

Lisebelisoa tsa mochini o lebelo le phahameng li hloka nako e khuts'oane haholo ea "block" (PA e fihla ho 7200 blocks / sec) le li-algorithms tse khethehileng tsa taolo le mesebetsi ea puisano."Tsamaiso ea ho bala pele" e tla sebetsa pele ho li-blocks tse 1000 ka lenaneo la nako ea sebele, 'me e bale tekanyo e phahameng ea phepo ka har'a li-parameter le meeli ea ho finyella litlhoko tsa machining a rarahaneng.

Ho nepahala

Litlhoko tsa tlhahiso e phahameng, ho nepahala ho phahameng le boleng bo botle ba ho qeta holimo li ntse li eketseha.

Sehokelo sa mochini oa batho

Mesebetsi e phethahetseng ea ho hlahloba ho fumana liphoso kapele;mefuta e fapaneng ea ho itšeha likhase tse thusang li ka fetoloa habonolo ka mokhoa oa ho laola lipalo.

E na le laeborari ea li-paramethara tsa setsebi sa laser le sehokelo sa paramethara sa setsebi se bonolo sa mosebelisi, se ka fetolang liparamente tsa ts'ebetso ea laser ka nako ea nnete sebopehong.

Khokahano ea puisano ea Ethernet e ka buisana ka kotloloho le komporo mme ea fetisa lifaele tsa karolo ea lenaneo.Ka pontsho ya boemo le tshebetso ya pontsho ya boemo ba hajwale.

Sebaka sa polokelo ea li-hard disk ke 250G, 'me lenaneo la ts'ebetso le ka bitsoa ka ho toba ho tswa ho hard disk, kahoo ha le felle ka mohopolo oa tsamaiso.Ts'ebetso ea tlhahlobo ea hole, sistimi ea servo ea dijithale.Pontšo ea LCD ea mebala.

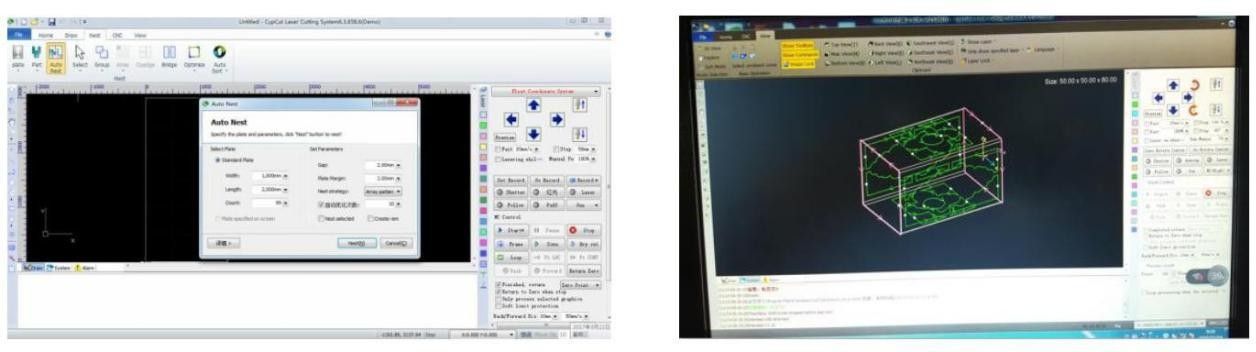

(8) Moralo oa lenaneo le software ea ho haha sehlaha

Cypcut le Cuytube ke sistimi e matla ea ho itšeha ea tšepe le software e bohlale ea ho seta, ho kenyeletsoa ts'ebetso ea laser cutting process, mesebetsi e tloaelehileng ea lihlaha le taolo ea ts'ebetso ea laser.Mesebetsi ea mantlha e kenyelletsa ts'ebetso ea lits'oants'o, ho hlophisoa ha paramethara, ho hlophisoa ha mokhoa oa ho itšeha, sebopeho, moralo oa tsela, ketsiso, le taolo ea ts'ebetso ea ho itšeha.

9. Sistimi e phodileng

Adopt Wuhan Hanli chiller system ho pholisa jenereithara ea laser, ho pholisa hantle likarolo tsa optical le hlooho e sehang.Setsi sa ho futhumatsa se na le potoloho ea metsi a pholileng a koetsoeng.

10. Li-air conditioner tsa indasteri

Li-conditioner tse phahameng tsa indasteri tse inehetseng li sebelisoa ho etsa bonnete ba hore moea o hloekileng le mocheso o ka hare ho khabinete, taolo e bohlale ea boiketsetso, taolo e bohlale ho latela mocheso o teng ka har'a kabinete, ts'ireletso ea filthara habeli, e ikamahanyang le maemo ka botlalo maemong a thata joalo ka tikoloho e futsanehileng, lerole le phahameng, le mocheso o phahameng.Ntlafatsa haholo bophelo ba ts'ebeletso ea likarolo tsa motlakase tse nepahetseng.